Liquid colors, additive concentrates and dosing systems

Whether thermoplastic, thermoset or Elstomer – ROWASOL liquid colors or color pastes are suitable for the sustainable coloring of many polymers and bio-thermoplastics!

Product video: ROWASOL liquid colors

Sustainable coloring

Liquid colors were designed to make plastic coloring more efficient and therefore more sustainable.

Learn more about here !

Structure of our liquid colors

For our liquid colors or color pastes, we use commercially available pigments or dyes, as they are also used in conventional masterbatches. Special wetting agents and rheology additives ensure a high optimal distribution of the pigments and stability of the dispersion. Thus the Maximum color intensity and prevents the pigments from settling for a long time. The actual carrier is a non-volatile, high-molecular system that is optimally distributed in the plastic melt and does not migrate out of the end product due to its excellent compatibility. If required, a bio-based carrier system can be used, e.g. for coloring bioplastics or recyclates.

Manufacturing process

Our products are produced by highly effective mixing batchwise produced. It is dispersed until the pigments are optimally distributed in the carrier. Optional post-processing and filtration of the colors guarantees a particle fineness of up to 1 µm. Since there is no thermal energy input during manufacture, the production-related Extremely low CO2 footprint.

Color matching

Whether RAL, NCS or Pantone, opaque or transparent, fluorescent or effect pigment – we can fulfill almost any wish! As a member of the COLOR COMPETENCE CENTERS we are optimally networked with the know-how and resources of the ROWA GROUP and find the optimum solution even for difficult problems.

For a color adjustment contact Please contact us! You are also welcome to send us in advance a completed customer inquiry form and send it to us.

Of course, you can also obtain monopigment concentrates from us for self-coloring. You can find more information on this under Advantages.

Standard packaging

As standard, we offer our products in the containers shown on the left, but we are also happy to fill them in customer-specific containers.

ROWASOL COLOR CUBE

Our reusable containers for cost-efficient and resource-saving coloring!

Learn more here more about the ROWASOL COLOR CUBE!

Additives from Rowasol

Available additives

We offer the following additives as standard for a wide range of plastics:

– Light stabilizer

– Antistatic agents

– Lubricant

– Laser additives for laser marking

– Antioxidants

– Plagiarism protection from Tailorlux (see below)

Of course, we also realize customer-specific solutions –just contact us at !

Plagiarism protection, digitization and traceability

We are a contract manufacturer for Tailorlux in Münster in the field of marker dispersions, which are used for the unambiguous identification of the origin of products. Further information and contact persons can be found at tailorlux.com.

Combi-batch

We combine function and color individually according to customer requirements, so that you only need one dosing unit for liquid media to equip your plastic.

Rowametric dosing systems

We will be happy to advise you personally on the selection of the optimum ROWAMETRIC dosing system!

Product video: ROWAMETRIC dosing systems

Peristaltic pumps

Progressing cavity pumps

Gear pumps

Comparison of the ROWAMETRIC systems

| Peristaltic pump | Progressing cavity pump | Gear pump | |

|---|---|---|---|

| Application | Injection molding/extrusion | Injection molding/extrusion | Extrusion |

| Dosing location | via feed | via feed | via feed or in polymer melt |

| Dosing range | from 1 ml/min | from 0.1 ml/min | from 0.03 ml/min |

| Color change | Tube change | Pump head cleaning or change | Pump head cleaning or change |

| Main advantage | Fast color change | pulsation-free even with low dosing | Color injection also possible in melt |

| Field of application | Frequent color changes, high color variety, small batch sizes | few color changes, low color variety | Continuous processes, few color changes |

Manuals

Gravimetric extrusion

Extrusion Volumetric

Injection molding

Gravimetric

Injection molding Volumetric

Other documents

Standard packaging

As standard, we offer our products in the containers shown on the left, but we are also happy to fill them in customer-specific containers.

ROWASOL COLOR CUBE

Our reusable containers for cost-efficient and resource-saving coloring!

Learn more here more about the ROWASOL COLOR CUBE!

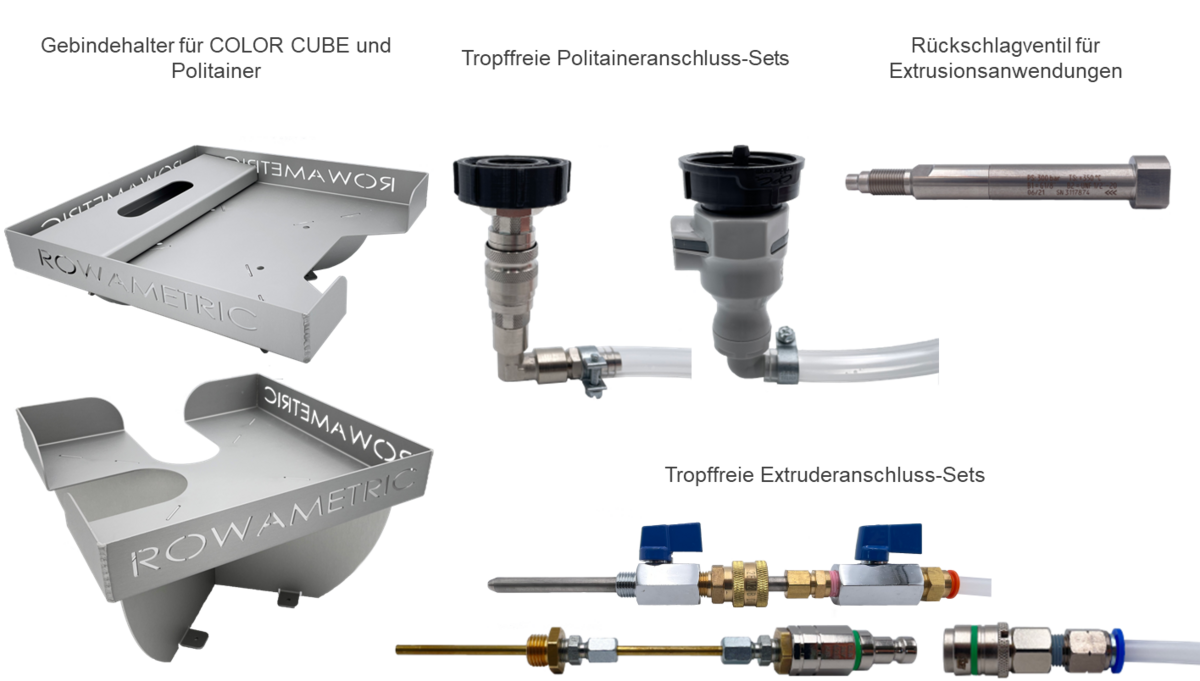

Accessories (selection)

Our cooperation partners

THE ROWASOL COLOR CUBE

The reusable system for environmentally friendly and cost-conscious coloring of your products

Our resource-saving reusable container

Concept and advantages at a glance

Large selection of colors

From the idea to the product

We support you right from the start and offer you the ideal start to liquid coloring with our service package!

Initial consultation

First of all, the optimization potential for the use of liquid color is determined in an initial consultation. The focus here is on the current coloring method and the application-specific requirements. Advantages by switching to liquid paint. In addition, the paint in question ROWAMETRIC dosing system discussed. Depending on the manufacturing process and the coloring, different pumps can be used. For small batch sizes and many color changes, the peristaltic pump is the dosing device of choice. For “continuous runners” or very low dosages, the progressive cavity pump may be the best solution. And if the color is to be continuously injected into the melt under high pressure, the gear pump is used.

Color matching

Are all key data and a suitable project has been identified, we begin with the reproduction of one or more colors according to the customer’s template. It does not matter whether it is a RAL, NCS or Pantone color, whether it should be opaque or transparent and contain fluorescent or effect pigments – we fulfill almost every wish! Of course, the color can also consist of monopigment concentrates if the goal is self-coloring with “monos”.

An initial profitability analysis can then be carried out based on the resulting liquid color dosage and the sales price. As liquid coloring offers many other advantages in addition to lower coloring costs, all aspects of the production process must be considered in the cost analysis.

Operational tests

The liquid colors and additive concentrates of the ROWASOL are an alternative to conventional masterbatches. They consist of pigments or dyes that are dispersed discontinuously at room temperature in a solvent-free, liquid carrier system. Special wetting agents and rheology additives ensure optimum distribution of the pigments and stability of the dispersion. Depending on the application, the use of liquid colors can provide advantages in terms of the amount of colorant used, the homogeneity of coloring, color change times and storage. In addition to customer-specific color settings, we also offer optimally pre-dispersed monopigment concentrates that allow the user to make their own color settings to achieve maximum flexibility.

Follow-up service

We always offer the initial consultation, the color adjustment and the operational test as part of an initial sampling with a quantity of up to 5 kg per color free of charge free of charge.

And even beyond this initial phase, we offer excellent follow-up service, for example when it comes to setting up the color portfolio or installing the dosing technology.

This risk-free service package for you – coupled with optimum dosing technology – enables us to get everyone involved in the project, from production staff to management, excited about liquid coloring. To benefit from our service, Contact us simply by phone, e-mail or via our online form!

ROWASOL as your extended workbench

ROWASOL GmbH also offers you flexible and efficient production at the highest quality level in the area of contract manufacturing.

Take advantage of the know-how of our experts, who will accompany you from the concept of your dispersed product through to packaging and, if necessary, dosing. We offer competent service from a single source – use our contract manufacturing to relieve your core processes and delegate specific work processes to your extended workbench: ROWASOL.

Our Mr. Schulz will be happy to answer your questions about contract manufacturing!