Recyclate coloring

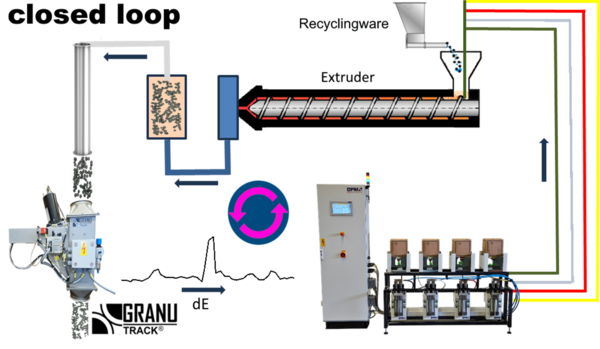

- NEW: The CLOOPMIX® system from OPM for inline coloring of recycled materials

- Precise liquid color dosing

- Intelligent recipe management

- Real-time color control with GranuTrack®

- Automatic adjustment by intelligent control algorithm in the event of color deviations

- Consistent color quality despite material fluctuations, with color deviations of less than ΔE 1

- ⇒ Brochure

Product video: Recyclate coloring

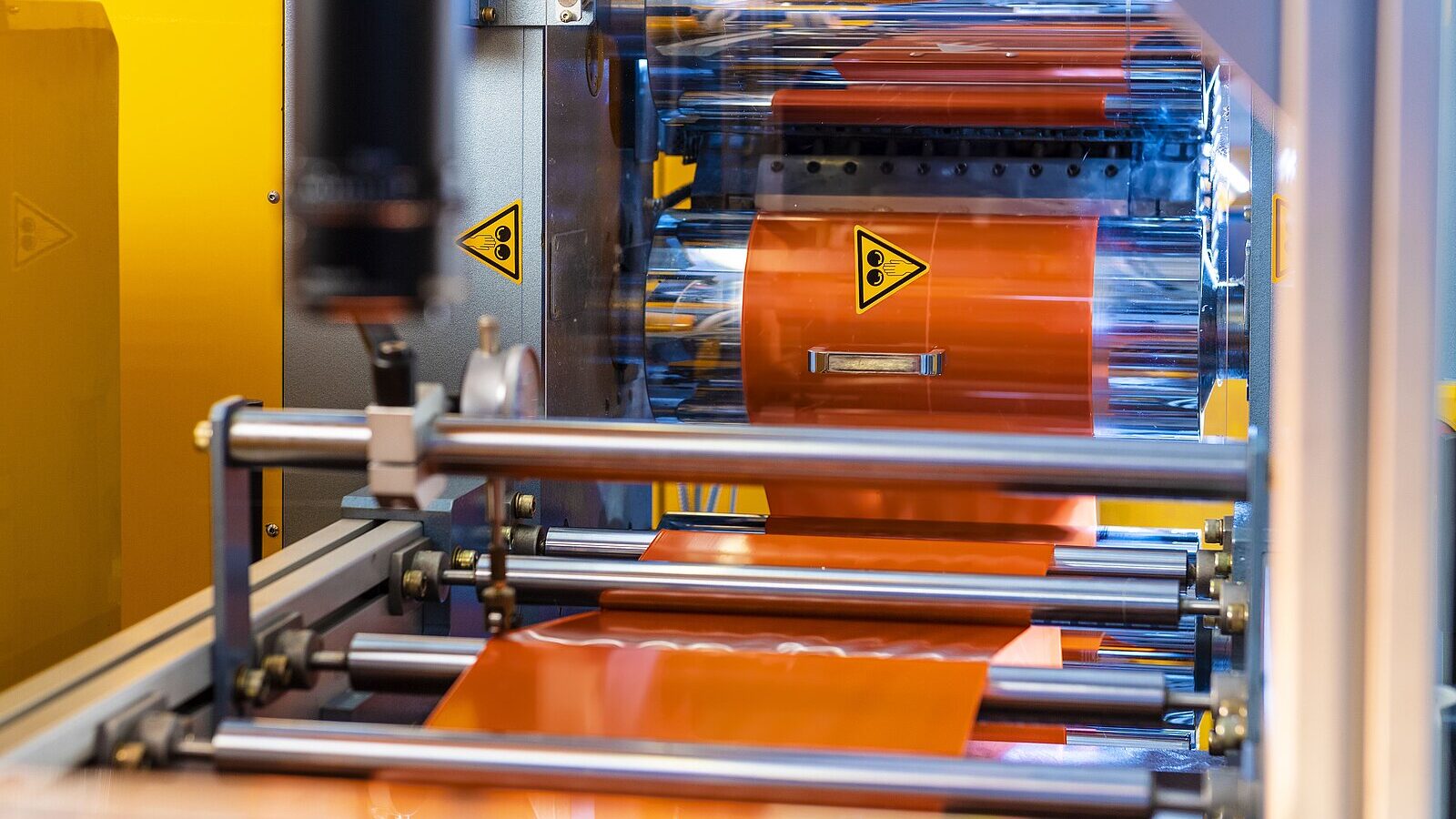

Extrusion

- Films ⇒ Streak and stain-free

- Compounds ⇒ Efficient self-coloring

- Profiles and fibers ⇒ Reduction in dyeing costs

- Color injection downstream ⇒ Time and material savings when changing colors

- Examples: ABS edgebands, PVC skirting boards, technical compounds, PP films, PVC flooring, PP fibers, HD-PE sheets, filaments for 3D printing, PVC window profiles and much more.

Injection molding

- Thick-walled opaque parts ⇒ Savings potential for coloring costs, uniform coloring

- Thin-walled transparent parts ⇒ less dosing, no specks, no streaks

- Hot runner ⇒ fast color changes (30 % – 50 % fewer cleaning cycles)

- Engineering plastics (TPU, PBT, PA, ABS, etc.) ⇒ Low raw material costs

- Commodities (PE, PP, PS) ⇒ Reduction of the amount of colorant

- Examples: PP pin sleeves, TPU shoe soles, PE and PP closures, PC and ABS containers, PS cutlery, and much more.

Mixing with liquid pre-products

- LSR ⇒ silicone oil as a carrier – also with approval for food contact on request

- PVC ⇒ PVC plasticizer (plastisol) can be used as a carrier for liquid paint or paint paste, making it 100% compatible

- Reactive resins and foams ⇒ Liquid color is premixed in one of the liquid components, e.g. with polyol for PUR

- Examples: Silicone components, acrylic resin sheets, PVC exercise balls, PU integral foams, flexible PU foams, PU shoe soles, adhesives, sealants, PVC boat fenders and buoys, and much more.